Interpreting Test Results when The Cable is neither Good nor Bad

Navigating the Ambiguity of PASS* and FAIL*

We always want to get the most value out of our investments. Looking at copper and fiber cabling plants, one of the best ways to gain more value is to ensure it comes with a long-term replacement warranty directly from the cable manufacturer. Obtaining a full manufacturer’s warranty can only be accomplished through cable certification testing. Without proving passing certification test results, your cabling will not be fully covered by most manufacturer warranties. In this article, we’re going to explore what a cable manufacturing warranty is, why you want one and how to best obtain a warranty for future cable installs.

This warranty guarantees the physical cabling is free from any type of defect. Yet, this can only be confirmed or denied if the manufacturer has assurances that the install was appropriately handled. Bad fiber or copper terminations can make it look like the problem has to do with a physical defect with the cabling itself. Thus, for the manufacturer to honor cabling warranty for copper and fiber, whomever is installing the cabling plant must perform stringent cable certification tests and submit the passing results to the manufacturer. Only then will the cable plant be fully covered under the manufacturer’s warranty.

By using a proper certification test tool to verify both the cabling and installation meets the manufacturer’s standards, you gain added value, peace of mind and protection against costly outages due to physical-layer issues.

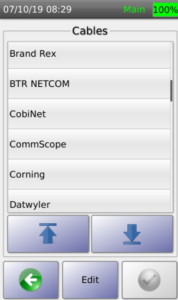

AEM CV100 With Built-in Cable Certification Specifications

Value is gained in the fact that future network upgrades will not have to be concerned about the cable plant when upgrading the network to run at faster speeds. Without this certification and the corresponding warranty, upgrading a network to achieve faster speeds may result in unforeseen physical layer problems where cabling must be replaced at the customer’s expense. What many organizations are discovering with non-certified and no-warrantied cabling is that the cabling they use today works fine for gigabit and lower speeds. Yet, when moving up to higher transmission rates such as 2.5, 5 and 10Gbps Ethernet, physical layer problems crop up. The reason for this is that the cabling is more sensitive to manufacturing and installation defects when operating at faster throughput rates. Thus, a network upgrade project can end up costing significantly more if portions of the cable plant must be replaced.

If, however, the cabling was certified using a tester such as the AEM TestPro CV100, a passing result not only certifies the cabling can operate at 1Gbps speeds – but also at multi-gigabit speeds for both twisted pair copper and single/multimode fiber. The best part is, the CV100 can perform a one-touch certification Autotest for CAT6A cables in only 6 seconds. Thus, certifying even very large cable installs to meet the manufacturer’s warranty requirements has never been faster or easier.

AEM CV100 One-touch Certification Autotest Screen

Acquiring a fully certified manufacturer’s warranty should also be thought of as an insurance policy against future outages caused by any physical-cabling defect. Once a cable plant is put into production, even a short outage lasting a few minutes can significantly impact an organization from an operational and profitability point of view. Depending on the type and duration of the outage, it can cost a company hundreds to thousands of dollars in lost revenue. The piece of mind to be running fully warrantied copper and fiber is an added layer of protection against outages that may crop up due to poorly made or installed cabling.

Lastly, certifying and fully warrantying copper and fiber is not only beneficial to the end customer – it’s beneficial to the cable install contractor as well. The contractor is no longer obligated to back the quality of the cabling themselves. Instead, having a manufacturer-backed warranty removes any risk the installing contractor may have in terms of physical defects to the cabling that may be discovered down the road. Thus, if any faults in the cabling were to be identified in the future, it is replaced at the manufacturer’s expense. In the end, both the end-customer and the structured cabling contractor benefit. That’s why proper certification testing to achieve a full warranty is so important.

Ready to learn more about how AEM's award-winning test solutions can help you achieve your cable testing needs? Request a demo with our team.

View listing of AEM TestPro warranty approvals.

Navigating the Ambiguity of PASS* and FAIL*

In the world of structured cabling, it’s common to hear the terms verification, qualification,...

Managing time on any cable install project can be a challenge. For large CAT6A installs, it can...

Leave a comment