Certi-Lite: At the Heart of a New Category in Cable Test

Due to an increased reliance on network-connected technologies in the enterprise, IT departments...

Navigating the Ambiguity of PASS* and FAIL*

Cable certification tests ensure that installed cabling meets application requirements in real-world network environments. When a cable passes (PASS), it is deemed good. When it fails (FAIL), issues must be resolved before approval. However, there are cases where the certifier provides ambiguous results either *PASS or *FAIL, requiring careful interpretation.

Understanding *PASS and *FAIL

To grasp these ambiguous results, we must consider the standard that defines accuracy requirements for cable certification testers. The TIA-1152A standard specifies accuracy levels for various parameters, with the highest stringency applied to Level 2G testers, which are suitable for CAT8 cable certification. While this discussion applies broadly, we will focus on two key parameters: Return Loss and Length Accuracy.

Return Loss

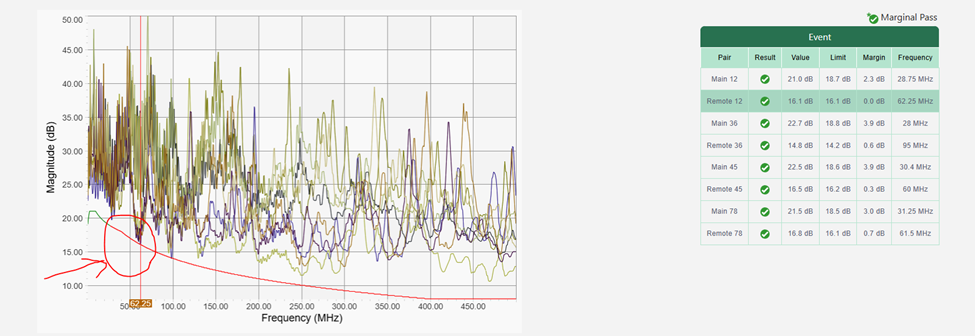

For Level 2G testers, return loss measurement accuracy for permanent link testing must be within ±1.4 dB. This strict requirement applies across thousands of frequency points per wire pair and must not deviate beyond 1.4 dB from a reference measurement (typically conducted with a laboratory-grade vector network analyzer).

This means that a cable barely passing could be reported as PASS with a +1.4 dB margin or FAIL with a -1.4 dB margin, creating ambiguity for installers, end-users, and consultants involved in cabling validation.

To address this, cable certifiers mark results with small positive margins as PASS* and small negative margins as FAIL*. The AEM TestPro offers higher accuracy than TIA-1152A requirements, setting PASS* at 0.5dB and FAIL* at -0.5dB.

For example, a cable with a 0.0 dB margin may be reported as PASS*. If one frequency point, such as 62.25 MHz on remote pair 12, has a 0 dB margin, the overall result is flagged as PASS* or Marginal PASS.

Length Accuracy

The TIA-1152A standard specifies accuracy for length measurement, but it is important to note that a tester does not directly measure length. Instead, it calculates length based on round-trip signal delay from the main unit to the remote unit and back. Using the Nominal Velocity of Propagation (NVP), the tester derives and reports the length.

According to TIA-1152A, length accuracy is ±1m plus a proportional error of 4% of the measured length. For a 50m cable, this allows an error of ±3m. However, modern cable certifiers, such as AEM TestPro, provide much better accuracy, typically within ±1m for a 50m cable.

It is also crucial to recognize that cable pairs usually have slight length variations. The certifier reports the length of the shortest pair. Given these factors, pair-to-pair variations, NVP dependency, and tester accuracy, it is not advisable to use reported length for purposes like determining material costs or technician payouts.

Options for Handling Marginal Cases

How PASS* and FAIL* results are interpreted depends on customer preferences. The following approaches are common:

Ultimately, there is no absolute method for interpreting marginal results. This article provides guidance to help make informed decisions based on your requirements.

Due to an increased reliance on network-connected technologies in the enterprise, IT departments...

Managing time on any cable install project can be a challenge. For large CAT6A installs, it can...

With increasing requirements to connect bandwidth intensive smart devices in networks, there is a...

Leave a comment