Comparing Copper Cable Certification Standards

Field testing of network cables is an important step in ensuring good quality of installation....

.jpeg)

A new and exciting cable standard has recently been announced. Technically speaking, it’s known as IEEE 802.3cg. Yet, in most cases, it’s simply called single pair Ethernet — or SPE — for short. In this blog, we’re going to look at why SPE is a far better option in specific cabling situations when compared to running standard 4-pair Ethernet such as CAT6A. We’ll also look two industry and enterprise use case scenarios where SPE is growing in popularity due to inherent advantages it has over thicker and heavier Ethernet cabling alternatives.

Situations where 4-pair Ethernet cables fall short

If you look at the evolution of four-pair Ethernet, you’ll notice that a CAT6A cable has grown substantially larger and thicker compared to a CAT5 and CAT3 cable standards that preceded it. The reason for this is two-fold. First, the gauge of the wires are becoming thicker so it can more reliably transport data at multi-gigabit speeds. Second, the thicker gauging and shielding is needed to help prevent power loss of endpoints that require 60-90W of power over Ethernet (PoE) up to 100 meters. The added thickness also helps to dissipate extra heat generated when higher wattage power is used across multiple lines in a cable bundle.

That said, what if you don’t need more speed or power? What if you could deal with slower speeds and less power delivery with the added advantage of a smaller and lighter cable? In fact, that’s what many are discovering scenarios where Ethernet and power are required across the same line. In some instances, it would be better to give up the speed and power gains inherent in thicker 4-pair cabling if it meant a much smaller and lighter cable could be run. Additionally, there are some situations where running Ethernet well beyond the typical 802.3 limitation of 100 meters would be extremely useful. It’s for these three reasons — size, weight and distance — where typical 4-pair Ethernet is far from ideal.

Where SPE shines

The latest generation of SPE offers Ethernet data transport rates of 10 Mbps, full duplex. This may not seem like much considering CAT6A can run at speeds up to 10 Gbps full duplex. Yet, in many situations, a 10 Mbps max is more than enough throughput required. Additionally, the 802.3cg Ethernet specification uses the 802.3bu standard for power transport. This is also known as power over data line — or PoDL. The PoDL standard can power compatible devices belonging to 1 of 10 different power classes that range from 0.5 to 50 W of power to the end device. In many cases, 50 W of power is more than any single device would need.

SPE also has a second benefit that will be crucial for some enterprise deployment situations. Instead of a 100-meter distance limitation for both data and power over Ethernet (PoE) that’s common in 4-pair Ethernet standards, SPE supports cable lengths for data and PoDL up to 1 KM in length.

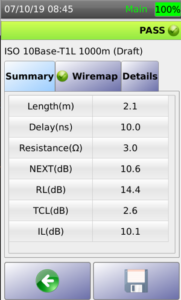

Example 802.3cg (10Base-T1L 1000m) test results

For deployments that span large buildings or even entire campus environments, extending the distance limitation 10-fold can be a major cost-saver.

Two common SPE Use cases

The first use case scenario where SPE has gained an enormous amount of traction is in the automobile manufacturing industry. Car makers are always looking for ways to make automobiles lighter. The lighter the vehicle, the more fuel efficient it becomes. Surprisingly, the wiring run throughout the entire vehicle of today’s automobiles is one of the heaviest components other than the chassis itself. Thus, if there’s any way to reduce the overall weight of the wiring harness – while also providing universal power and transport standards that can be used industry wide – auto manufacturers are jumping at the chance and looking to migrate to SPE for most cabling needs in next-generation vehicles.

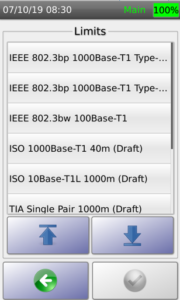

List of CV100 SPE Certification Test Limit Options

A second – and perhaps more mainstream – use case deals with the concept of an “everything connected” world. In the enterprise, this is called the Internet of Things – or IoT for short. IoT is the concept of connecting everything from temperature sensors to smart lighting to physical security systems to the Ethernet LAN. Essentially, anything that can be connected and managed via Ethernet should and will be connected.

While IoT sounds great, it puts tremendous burden on the underlying cable plant to connect all these devices. In many buildings and building-to-building data conduits, there simply isn’t enough room to run the number of 4-pair Ethernet cables required. Additionally, overhead ladder racks that support the horizontal cable plant would need to be significantly reinforced in many areas to handle the added weight without buckling. Lastly, because there are situations where an IoT sensor might be deployed far away from the rest of the internal Ethernet LAN, a 100-meter maximum cable length limitation might not be enough. It’s in these IoT deployment situations where one can see the major benefits of SPE cablings being run up to 1000 meters in the enterprise.

SPE is a niche – but a growing niche

It might be easy to say that SPE is simply a niche standard that is useful in rare situations. While that may be true today, those situations are growing at a rapid rate. Just consider the fact that the number of IoT devices added globally will increase five-fold (an increase of 50 billion devices) by the year 2025. Once you comprehend that, you begin to see the magnitude of cabling that will be required — much of may just turn out to be SPE.

Ready to learn more about how AEM's award-winning test solutions can help you achieve your cable testing needs? Request a demo with our team.

Field testing of network cables is an important step in ensuring good quality of installation....

Managing time on any cable install project can be a challenge. For large CAT6A installs, it can...

Enterprise cabling systems are going through a big paradigm shift. In the past, one of the main...

Leave a comment